铝电解电容器虽说是较为常用的一种电子元器件,但其本身很容易受到高温和低温等极端条件的影响,而导致元器件损坏。如何有效的规避这些问题,就要根据铝电解电容本身的特性进行分析。

Although aluminum electrolytic capacitor is a kind of common electronic components, it is easy to be affected by extreme conditions such as high temperature and low temperature, resulting in damage of components. How to avoid these problems effectively depends on the characteristics of aluminum electrolytic capacitor itself.

铝电解电容器在浸透电解液的纸片两面放置金属薄片。这种电解液会在电容器寿命期间蒸发,从而改变其电气属性。如果电容器失效,其会出现剧烈的反应:电容器中形成压力,迫使它释放出易燃、腐蚀性气体。

Aluminum electrolytic capacitors place metal sheets on both sides of the paper soaked in electrolyte. This electrolyte evaporates over the life of the capacitor, changing its electrical properties. If the capacitor fails, it will react violently: pressure is formed in the capacitor, forcing it to release flammable and corrosive gases.

电解质蒸发的速度与电容器温度密切相关。工作温度每下降10摄氏度,电容器寿命延长一倍。电容器额定寿命通常为在其最大额定温度下得出的结果。典型的额定寿命为105摄氏度下1000小时。

The rate of electrolyte evaporation is closely related to the capacitor temperature. When the working temperature drops by 10 ℃, the life of the capacitor is doubled. The rated life of a capacitor is usually the result obtained at its maximum rated temperature. The typical rated life is 1000 hours at 105 degrees Celsius.

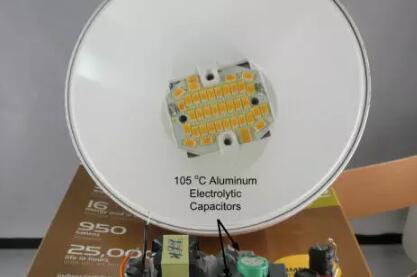

选择这些电容器用于图1所示LED灯泡等长寿命应用时(LED的寿命为25000小时),电容器的寿命便成了问题。要想达到25000小时寿命,这种电容器要求工作温度不超过65摄氏度。这种工作温度特别具有挑战性,因为在这种应用中,环境温度会超出125摄氏度。

When these capacitors are selected for long-life applications such as the LED bulb shown in Figure 1 (the LED life is 25000 hours), the capacitor life becomes an issue. To achieve a life of 25000 hours, the capacitor requires an operating temperature of no more than 65 degrees Celsius. This operating temperature is particularly challenging because in this application, the ambient temperature can exceed 125 degrees Celsius.

市场上有一些高额定温度的电容器,但是在大多数情况下,铝电解电容器都将成为 LED灯泡寿命的瓶颈组件。

There are some capacitors with high rated temperature on the market, but in most cases, aluminum electrolytic capacitors will become the bottleneck component of LED bulb life.

图1:105℃电容器可能不会达到其声称的23年寿命

类似铝电解电容这种寿命温度依赖度实际影响了降低电容器额定电压的方法。首先想到的可能是增加电容器额定电压来最小化电介质失效的机率。但是,这样做会使电容器的等效串联电阻 (ESR)更高。由于电容器一般会具有高纹波电流应力,因此这种高电阻会带来额外的内部功耗,并且增加电容器温度。故障率随温度升高而增加。实际上,铝电解电容器通常只使用其额定电压的80%左右。

Similar to aluminum electrolytic capacitor, the life temperature dependence actually affects the method of reducing the rated voltage of capacitor. The first thought may be to increase the rated voltage of the capacitor to minimize the probability of dielectric failure. However, this will result in a higher equivalent series resistance (ESR) of the capacitor. Since capacitors generally have high ripple current stress, this high resistance will bring additional internal power consumption and increase capacitor temperature. The failure rate increases with the increase of temperature. In fact, aluminum electrolytic capacitors usually use only about 80% of their rated voltage.

电容器温度较低时,ESR急剧增加,如图2所示。在这种情况下,-40℃下,电阻呈数量级增加。这在许多方面都会影响到电源性能。如果电容器用于开关式电源的输出端,则输出纹波电压呈数量级增加。

When the capacitor temperature is low, ESR increases sharply, as shown in Fig. 2. In this case, the resistance increases in an order of magnitude at - 40 ℃. This affects power supply performance in many ways. If the capacitor is used in the output of the switching power supply, the output ripple voltage increases in order of magnitude.

另外,在ESR和输出电容形成的零以上频率,它让环路增益增加一个数量级,从而影响控制环路。这会产生一个有振荡的不稳定电源。为了适应这种强震动,控制环路通常会在空间方面做出巨大妥协,并在更高温度下工作。

In addition, at the frequency above zero formed by ESR and output capacitance, it increases the loop gain by an order of magnitude, thus affecting the control loop. This creates an unstable power supply with oscillations. In order to adapt to this strong vibration, the control loop usually makes a huge compromise in space and works at higher temperatures.

图2:低温下ESR性能急剧下降

通过以上分析可以发现,延长铝电解电容的使用寿命,主要是通过控制器工作温度来实现。

Through the above analysis, it can be found that extending the service life of aluminum electrolytic capacitor is mainly realized by the operating temperature of the controller.